The peeling is a machine tool for the production of wood ribbons having constant thickness, which can be set by the operator.

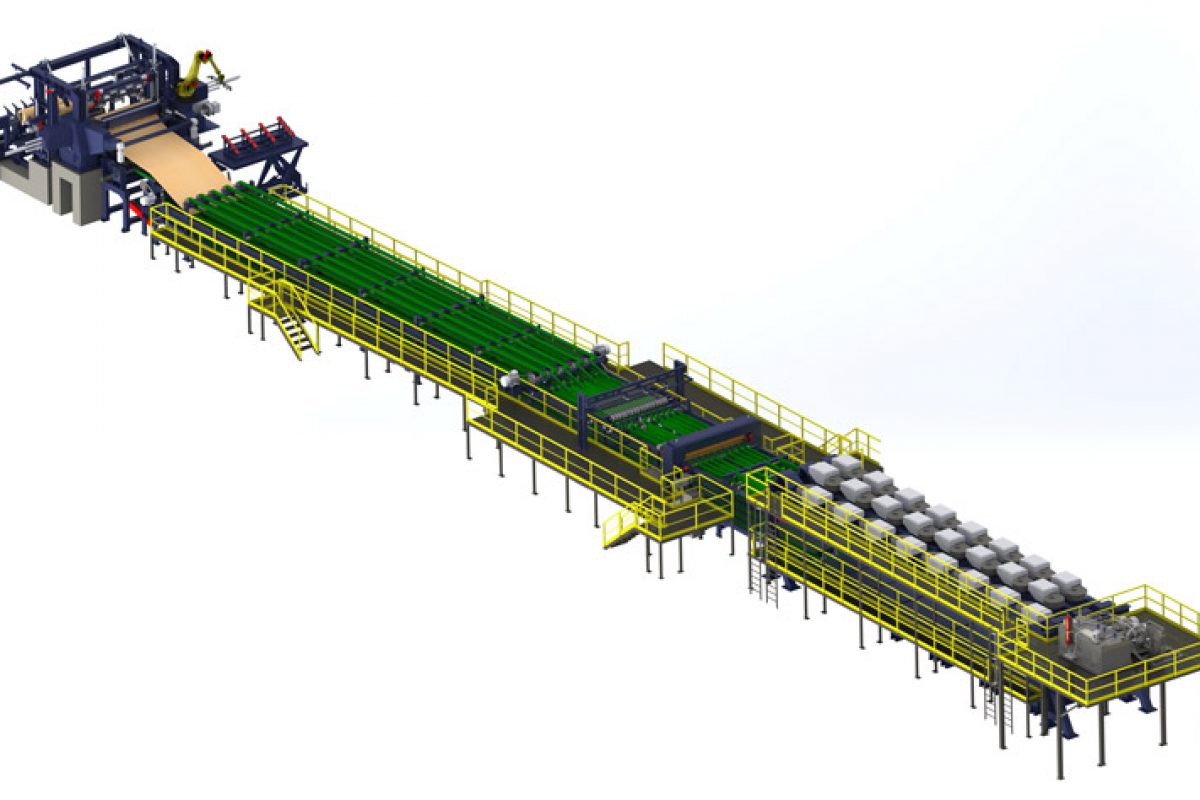

Purpose of the peeling lathe is to obtain, from a log, a small thickness sheet having a width equal to the log length and long as the spiral inscribable in the log section.

We can consider the log as roll of veneer that can be unwrapped. The smaller the thickness the longer the ribbon length.

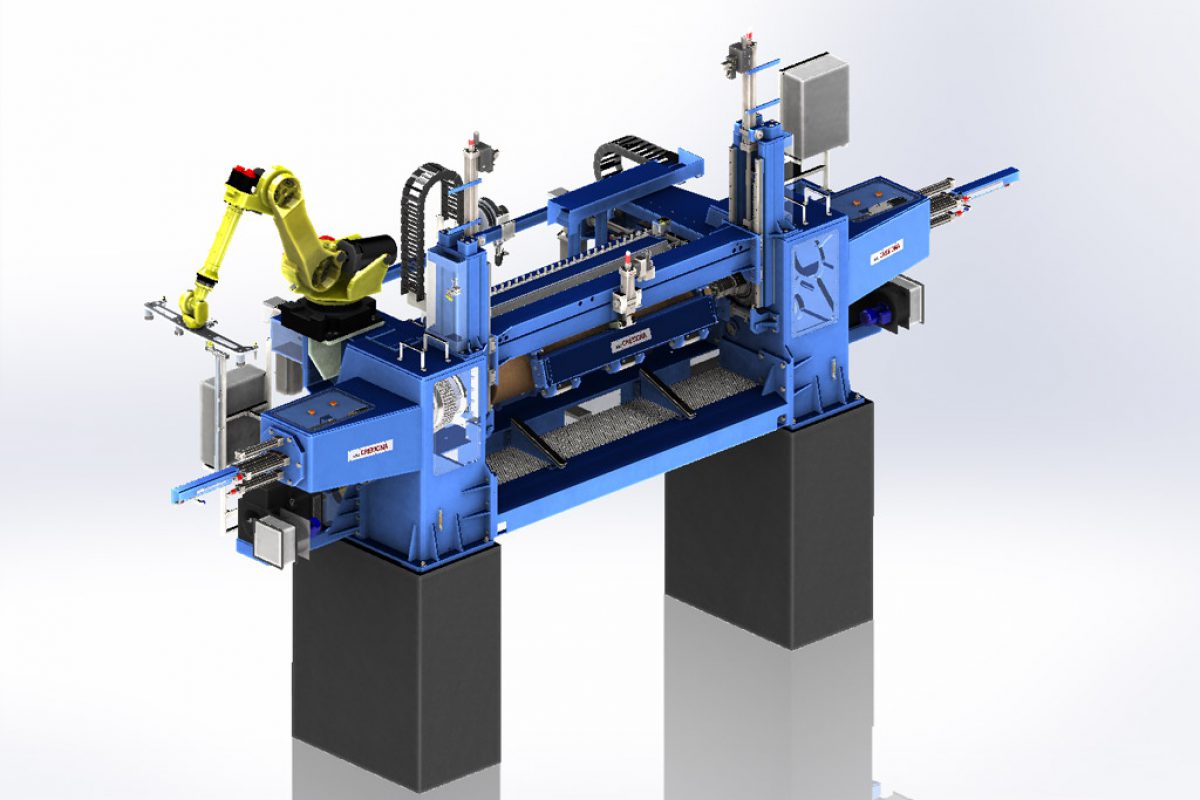

The machines must be able to grab the log on the two ends, using the jaws, put it in rotation and then approach the log with the knife, as large as the same log, and cut the wood to obtain the veneer.

The knife will advance towards the rotation axis in a constant way, and at each rotation will come nearer by an amount equal to the thickness of the veneer sheet to be obtained.

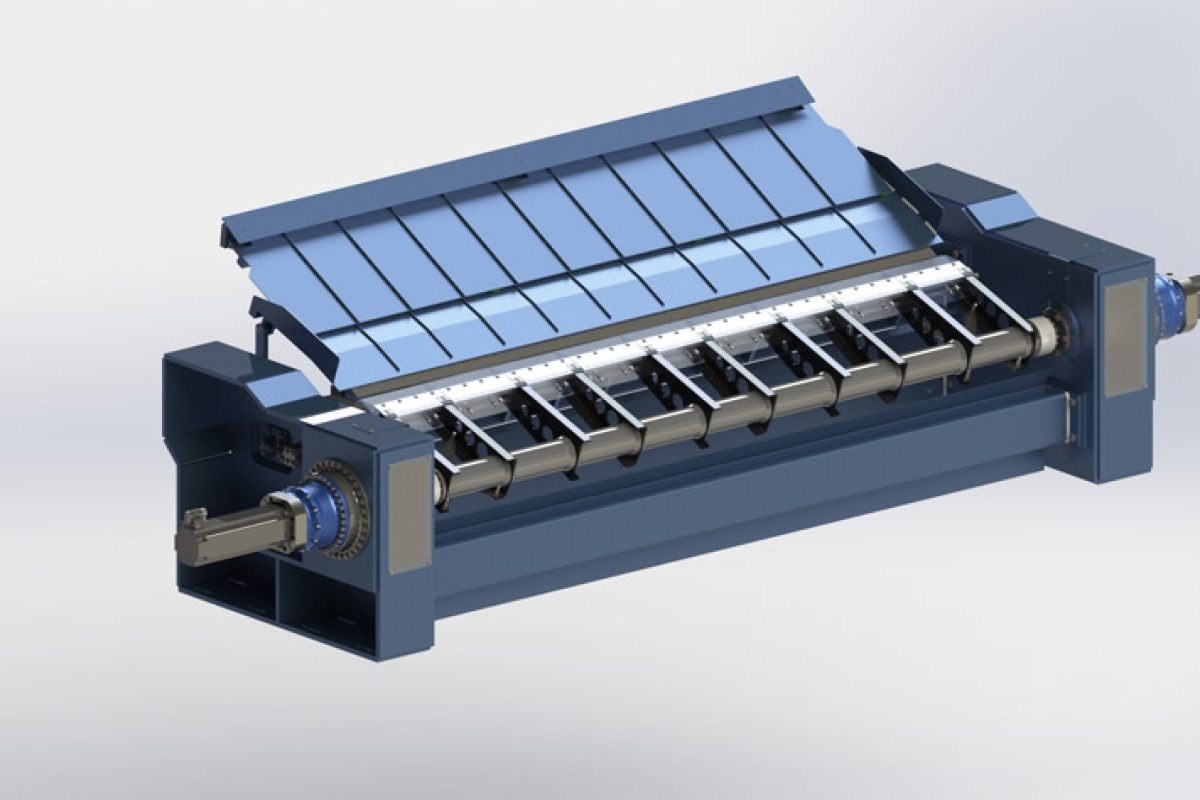

The veneer will be cut by the knife and laminated, on the top face, by a plate having rectangular section called nose-bar, which ensures its thickness.

During the peeling operation the log diameter will decrease and, to avoid it from flexing when it becomes smaller due to the action of the spindles that press it along its axis, a top beam will intervene to reduce the deformation of the log and keep it straight.

This device called back-up roll has a law of motion that ensures the synchronism with the knife. The distance between the rollers installed on the top part of the back-up roll, with regards to the center of rotation of the log, is always equal to the distance between the tip of the knife and the rotation axis.

The machine must therefore have a series of rotating movements, present in the spindles and in the rollers of the presser, displacement movements, of the blade with the bar and presser, managed as interpolated axes to obtain a constant size and good quality veneer.

The structure is composed of a base which carries two side supports, connected to one another by a stiffening beam at the top.

A core expulsion hole is found on the horizontal plane of the base.

Each side support houses 3 spindles.

The axial movement of the spindles is governed by a hydraulic system, while rotation takes place by means of a chain transmission.

The presser and knife holder carriage guides are mounted on the side supports.

The knife holder carriage houses a bar holder carriage, with positioning managed by means of hydraulic servocylinders.

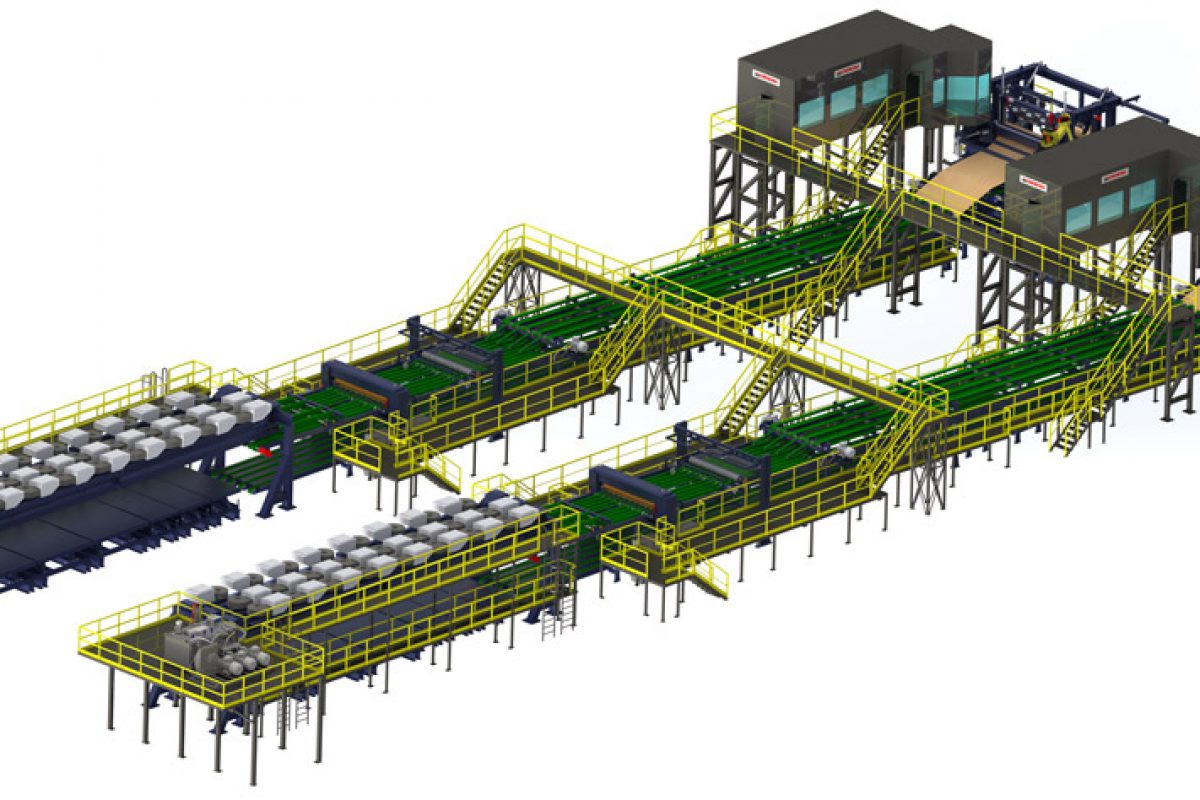

The peeling is a machine tool for the production of wood ribbons having constant thickness, which can be set by the operator.

Purpose of the peeling lathe is to obtain, from a log, a small thickness sheet having a width equal to the log length and long as the spiral inscribable in the log section.

We can consider the log as roll of veneer that can be unwrapped. The smaller the thickness the longer the ribbon length.

The machines must be able to grab the log on the two ends, using the jaws, put it in rotation and then approach the log with the knife, as large as the same log, and cut the wood to obtain the veneer.

The knife will advance towards the rotation axis in a constant way, and at each rotation will come nearer by an amount equal to the thickness of the veneer sheet to be obtained.

The veneer will be cut by the knife and laminated, on the top face, by a plate having rectangular section called nose-bar, which ensures its thickness.

During the peeling operation the log diameter will decrease and, to avoid it from flexing when it becomes smaller due to the action of the spindles that press it along its axis, a top beam will intervene to reduce the deformation of the log and keep it straight.

This device called back-up roll has a law of motion that ensures the synchronism with the knife. The distance between the rollers installed on the top part of the back-up roll, with regards to the center of rotation of the log, is always equal to the distance between the tip of the knife and the rotation axis.

The machine must therefore have a series of rotating movements, present in the spindles and in the rollers of the presser, displacement movements, of the blade with the bar and presser, managed as interpolated axes to obtain a constant size and good quality veneer.

The structure is composed of a base which carries two side supports, connected to one another by a stiffening beam at the top.

A core expulsion hole is found on the horizontal plane of the base.

Each side support houses 3 spindles.

The axial movement of the spindles is governed by a hydraulic system, while rotation takes place by means of a chain transmission.

The presser and knife holder carriage guides are mounted on the side supports.

The knife holder carriage houses a bar holder carriage, with positioning managed by means of hydraulic servocylinders.

Features

| Measures | |

| Power |

Certifications